Rasmus Raag & Siim Viilup

In this story, Siim and Rasmus each share three stories and their most vivid memories from their time at Starship, triggered by certain pictures or video clips.

Rasmus: The Birth of Starship

In July 2014, the seeds of Starship Technologies were sown in an apple garden, a setting that reflected both the simplicity and ambition of the budding company. Rasmus Raag, one of the early pioneers, recalls those formative days when they didn't even have an office yet. Their first meetings were held under the apple trees on nice summer days, sitting on the grass in a circle and discussing their future plans. These garden meetings occurred a few times until Ahti organized their first office, a single room at Akadeemia tee 21, within a few weeks.

The early days at Starship were characterized by a collaborative spirit and a strong sense of commitment. The team operated without a fully established workspace for almost a year, with mechanics working from the countryside and the first business personnel sometimes in the office, sometimes away. Despite the lack of formal infrastructure, everyone was deeply dedicated, with few taking vacations in that first year.

Social events were virtually nonexistent initially. The only gatherings were those early meetings in the garden, with no Christmas parties or birthday celebrations. It was only in 2015, after the arrival of Heidy Kerma, who brought a sense of social cohesion, that the team began to celebrate milestones together. Those early days were marked by intense technical discussions about everything from robot mechanics to climbing curbs, laying a strong foundation for the company's future.

Siim: How strong is our robot?

In the summer of 2017, our team embarked on a project to test a prototype of the current robot version i.e. 6E. The testing phase was both thrilling and nerve-wracking. Our goal? To see how this robot would endure under stress and pressure. With each trial, we learned valuable lessons about its performance and durability. The tests were rigorous and varied, pushing the limits of what our robot could withstand.

We subjected the robot to a series of intense trials. We dropped it from different heights, threw balls at it, and tested its waterproof capabilities in a pool. Our primary aim was to assess the strength of our very new version.

One memorable test involved launching the robot from a height of nearly two meters onto a grassy field. Despite the harsh impact, the robot survived remarkably well, sustaining only minor damage to a small corner. The picture captures our original testing ground, highlighting where the current version of the robot was put through its paces.

Testing also included assessing how resistant the robots are to being ridden. These trials were not just about testing durability; they were about understanding the robots' potential and limitations. Each drop, throw, and dunk provided insights that shaped the future iterations of the design.

It's the same video, but the colors indicate the direction of movement

How a 3D point cloud was made from the video

Rasmus: The Broomstick Camera

One of Rasmus Raag's most memorable experiences at Starship involves a broomstick, a camera, and the curious eyes of passersby. In the early days, with no prototype robot available, the team had to get creative to simulate the robot's perspective. It was the end of July, early August, and they needed footage to see what the robot might encounter, but they didn't have a robot yet.

Ingeniously, Rasmus attached a camera to a broomstick, allowing him to mimic the robot's low-ground perspective. He walked through the city center and Old Town, holding the broomstick with the camera on one end and a cable connected to a tiny laptop in his other hand. The unusual sight drew little attention, with most people assuming he was using a metal detector. Some people stopped him, curious about what he was doing, thinking he was scanning for metal objects.

This unconventional method yielded valuable insights. Reviewing the footage, Rasmus realized the need for privacy considerations. They needed to apply some kind of filtering because capturing high-quality footage from this angle wasn't great for privacy.

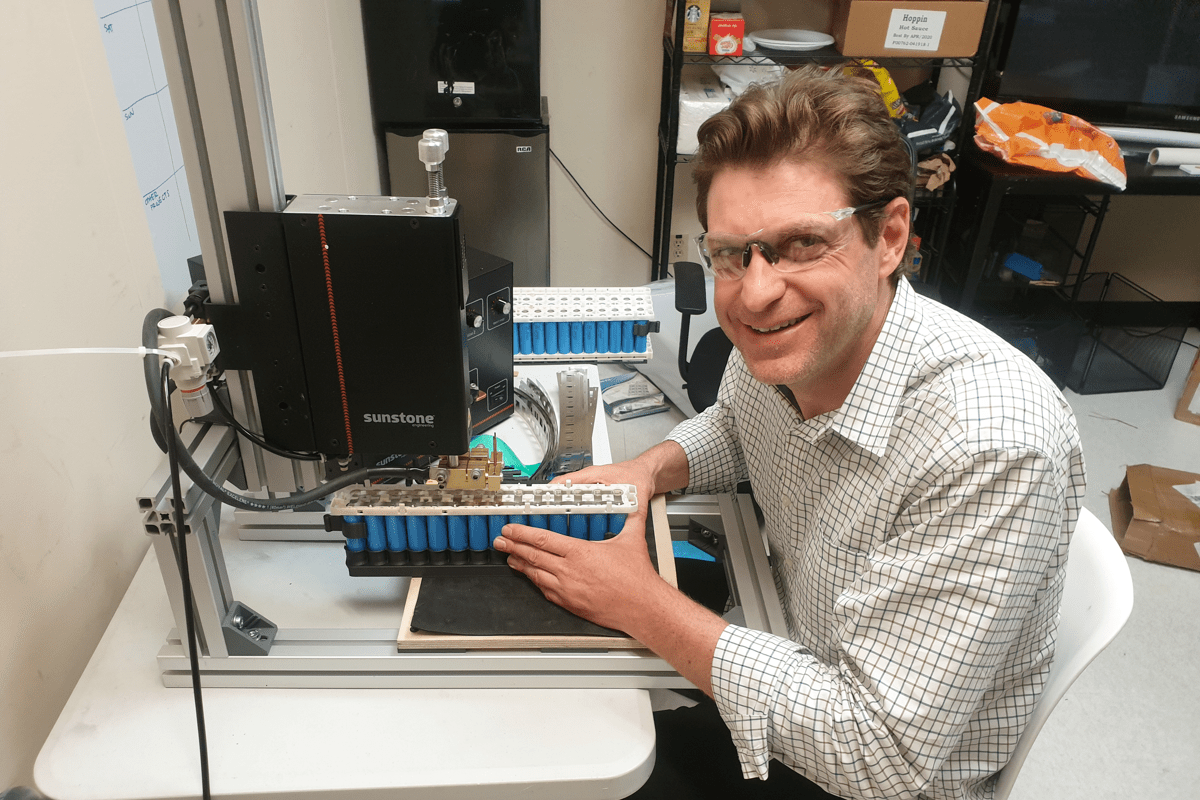

Siim: Transatlantic Battery

In 2019, we faced a significant challenge. Our existing small batteries lasted only a few hours and required constant replacement. Realizing this solution was neither efficient nor reliable, we quickly initiated a project to develop a larger battery that could endure operation from morning till evening—the same batteries we use today.

The project was intense and rapid. What would typically take a year in a conventional company, we accomplished in just three months. However, in the final phase of battery production, we encountered a major hurdle. We realized we couldn't manufacture the batteries in Estonia and then ship them to the U.S. due to the need for specific certifications, which our new product lacked.

With no quick alternative, we decided to produce the batteries in the U.S. Since I had designed the battery, I took on the responsibility usually handled by the production team and flew to the U.S. On-site, we needed to build 100 batteries. It was a strenuous task, even our CEO, Lex, was also fully involved and hands-on. Together with a team of three, we managed to produce the batteries over three intense days in San Francisco.

Once the batteries were ready, they still needed to be transported across the country to George Mason University in Fairfax, Va. Due to strict regulations, flying them was not an option. A field assistant had to drive them to their destination. Despite these obstacles, the project was a success

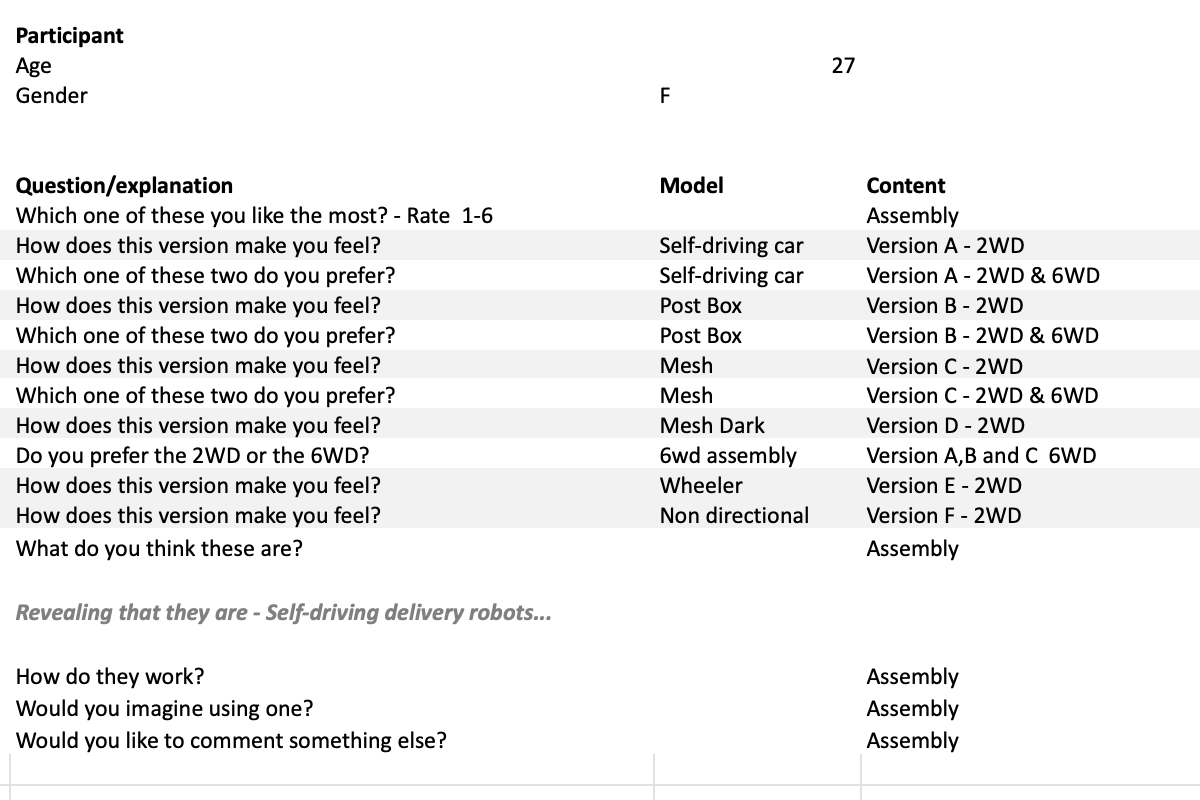

Rasmus: The Secretive Beginnings

The first year of Starship Technologies was shrouded in secrecy, adding an element of intrigue to the team's groundbreaking work. During this time, the team was in stealth mode, meaning they couldn't disclose their activities to anyone. They could mention they were working on robots, but the specifics of the delivery robot and its business model were closely guarded secrets. Rasmus Raag enjoyed the mystery, often responding to inquiries about his work with, "Sorry, I can't tell," which added a layer of intrigue.

This secrecy extended even to close friends and family, with one exception. There was a questionnaire about design preferences from an industrial design company in Finland, which Rasmus shared only with a very close friend, who is now his partner. This illustrates how those early days of mystery and exclusivity forged strong personal bonds.

Reflecting on those times, Rasmus sees the stealth mode as a unique chapter in Starship's history. It was a period of intense focus and quiet excitement, building something revolutionary with the added thrill of secrecy. This sense of shared purpose and camaraderie, born out of secrecy, has remained a cornerstone of Starship's culture as the company has grown.

Siim: The Cover Design Innovation

In late 2018, our team encountered a unique challenge in our quest to enhance urban mobility for robots. We needed to improve the efficiency of our robotic fleet, and a critical issue stood out: how can robots cross streets that require pressing a button?

To tackle this, our team developed a prototype for the robot's cover, incorporating a linear motor that allowed a part of the cover to move up and down. This prototype, named "Catapult," was designed to enable the robot to press crosswalk buttons. Despite the innovative design and even securing a patent for it, the Catapult never went into production because of its operational complexity and high manufacturing costs.

Looking ahead, we believe it will be more practical to automate these crosswalks, allowing robots to send a signal instead. This experience is just one example of the many unusual prototypes and solutions we've explored for our robots.

Already working at Starship Technologies?

Let’s recruit together and find your next colleague.